|

Hall’s Liliput Bank — Part 2

(Types I, II, III)

by Sy Schreckinger – ANTIQUE TOY WORLD Magazine – September, 2008

“Hall’s Liliput”, the mechanical bank selected

to be subject of this article, is one that is often perceived as

insignificant and lackluster. At first glance, it may compare unfavorably

to its "flashier" and more animated brethren. Closer inspection, however,

reveals a mechanical possessing elegance and dignity contained within its

simple design.

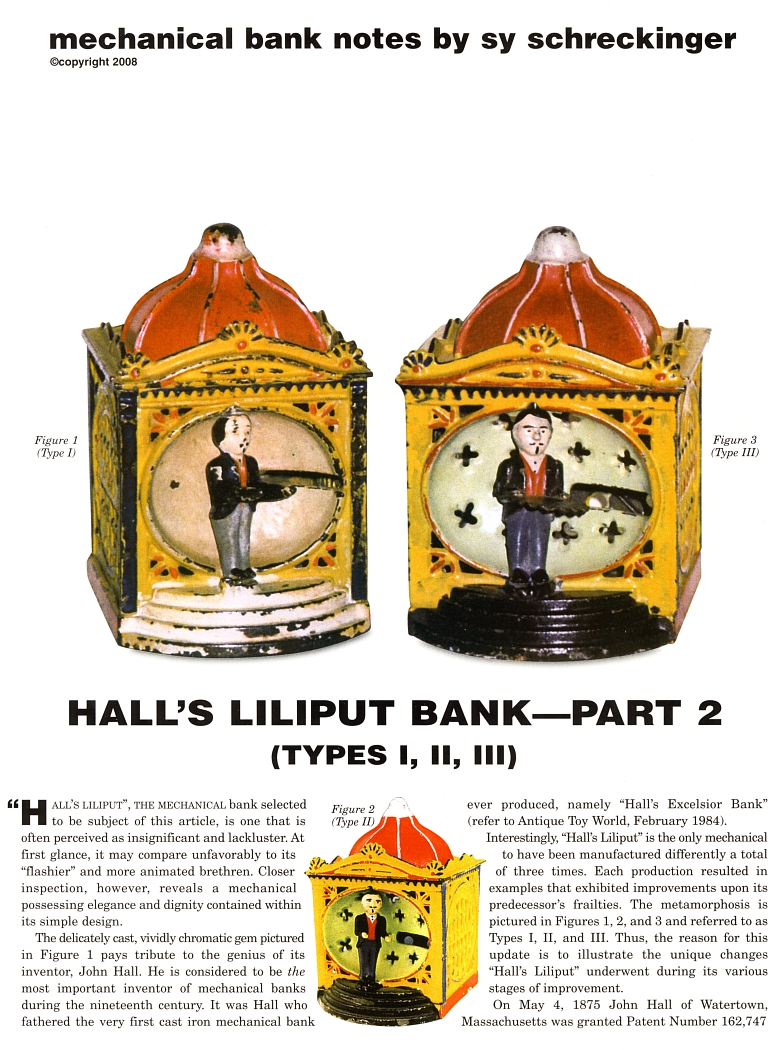

The delicately cast, vividly chromatic gem pictured in Figure 1 pays

tribute to the genius of its inventor, John Hall. He is considered to be

the most important inventor of mechanical banks during the nineteenth

century. It was Hall who fathered the very first cast iron mechanical bank

ever produced, namely "Hall's Excelsior Bank" (refer to Antique Toy World,

February 1984).

Interestingly, "Hall's Liliput" is the only mechanical to have been

manufactured differently a total of three times. Each production resulted

in examples that exhibited improvements upon its predecessor's frailties.

The metamorphosis is pictured in Figures 1, 2, and 3 and referred to as

Types I, II, and III. Thus, the reason for this update is to illustrate

the unique changes "Hall's Liliput" underwent during its various stages of

improvement.

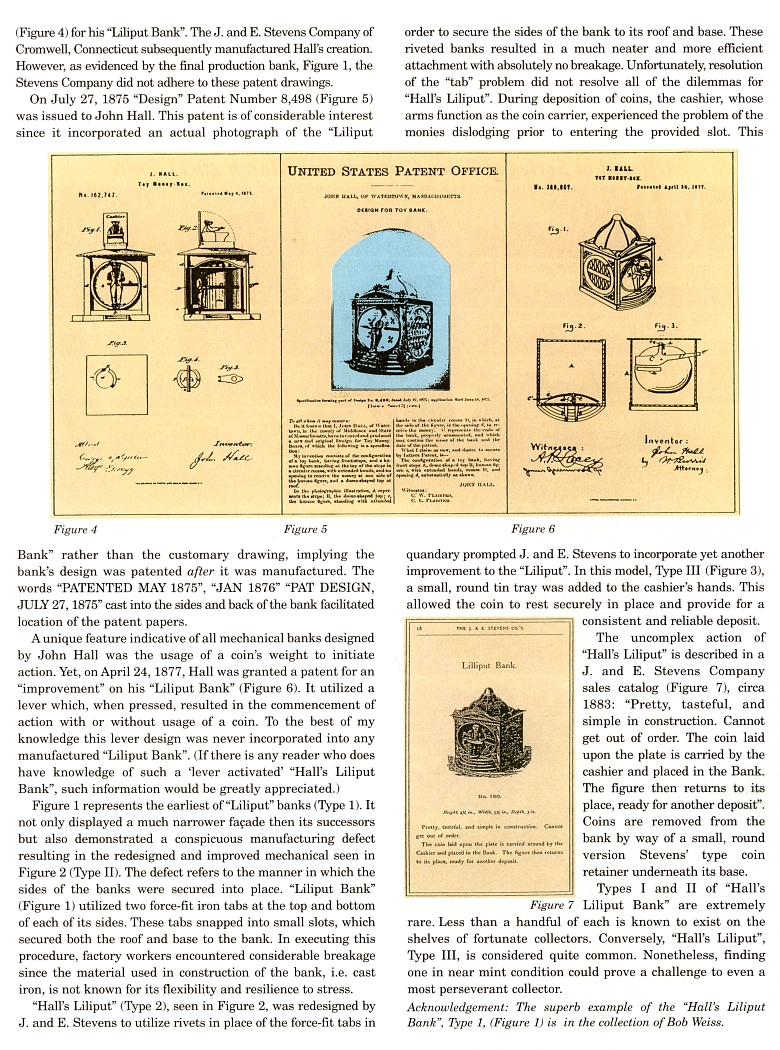

On May 4, 1875 John Hall of Watertown, Massachusetts was granted

Patent Number

162,747 HALL'S LILIPUT", THE MECHANICAL bank selected to be

subject of this article, is one that is (Figure 4) for his "Liliput Bank".

The J. and E. Stevens Company of Cromwell, Connecticut subsequently

manufactured Hall's creation. However, as evidenced by the final

production bank, Figure 1, the Stevens Company did not adhere to these

patent drawings.

On July 27, 1875 "Design" Patent Number

8,498 (Figure 5) was issued

to John Hall. This patent is of considerable interest since it

incorporated an actual photograph of the "Liliput Bank" rather than the

customary drawing, implying the bank's design was patented after it was

manufactured. The words "PATENTED MAY 1875", "JAN 1876" "PAT DESIGN, JULY

27, 1875" cast into the sides and back of the bank facilitated location of

the patent papers.

A unique feature indicative of all mechanical banks designed by John

Hall was the usage of a coin's weight to initiate action. Yet, on April

24, 1877, Hall was granted a patent for an "improvement" on his "Liliput

Bank" (Figure 6). It utilized a lever which, when pressed, resulted in the

commencement of action with or without usage of a coin. To the best of my

knowledge this lever design was never incorporated into any manufactured "Liliput

Bank". (If there is any reader who does have knowledge of such a 'lever

activated' "Hall's Liliput Bank", such information would be greatly

appreciated.)

Figure 1 represents the earliest of "Liliput" banks (Type 1). It not only

displayed a much narrower facade then its successors but also demonstrated

a conspicuous manufacturing defect resulting in the redesigned and

improved mechanical seen in Figure 2 (Type II). The defect refers to the

manner in which the sides of the banks were secured into place. "Liliput

Bank" (Figure 1) utilized two force-fit iron tabs at the top and bottom of

each of its sides. These tabs snapped into small slots, which secured both

the roof and base to the bank. In executing this procedure, factory

workers encountered considerable breakage since the material used in

construction of the bank, i.e. cast iron, is not known for its flexibility

and resilience to stress.

"Hall's Liliput" (Type 2), seen in Figure 2, was

redesigned by J. and E. Stevens to utilize rivets in place of the

force-fit tabs in order to secure the sides of the bank to its roof and

base. These riveted banks resulted in a much neater and more efficient

attachment with absolutely no breakage. Unfortunately, resolution of the

"tab" problem did not resolve all of the dilemmas for "Hall's Liliput".

During deposition of coins, the cashier, whose arms function as the coin

carrier, experienced the problem of the monies dislodging prior to

entering the provided slot. This quandary prompted J. and E. Stevens to

incorporate yet another improvement to the "Liliput". In this model, Type

III (Figure 3), a small, round tin tray was added to the cashier's hands.

This allowed the coin to rest securely in place and provide for a

consistent and reliable deposit.

The uncomplex action of "Hall's Liliput" is described in a J. and E.

Stevens Company sales catalog (Figure 7), circa 1883: "Pretty, tasteful,

and simple in construction. Cannot get out of order. The coin laid upon

the plate is carried by the cashier and placed in the Bank. The figure

then returns to its place, ready for another deposit". Coins are removed

from the bank by way of a small, round version Stevens' type coin retainer

underneath its base.

Types I and II of "Hall's Liliput Bank" are extremely rare. Less than

a handful of each is known to exist on the shelves of fortunate

collectors. Conversely, "Hall's Liliput", Type III, is considered quite

common. Nonetheless, finding one in near mint condition could prove a

challenge to even a most perseverant collector.

Acknowledgement: The superb example of the "Hall's Liliput Bank",

Type 1, (Figure 1) is in the collection of Bob Weiss.

|