|

The Detection of

Mechanical Bank Reproductions

(Part I)

by Sy Schreckinger – ANTIQUE TOY WORLD Magazine – November,

1993

A problem which may occasionally confront both

the novice and the experienced collector is the detection of reproduced

mechanical banks. Unfortunately, this situation has become increasingly

more frequent over the past few years due to prices of mechanical banks

which have risen to unprecedented heights. It is, therefore, advantageous

to be able to recognize recasts since knowledge acquired through education

and experience may minimize the possibility of unknowingly acquiring a

reproduced example.

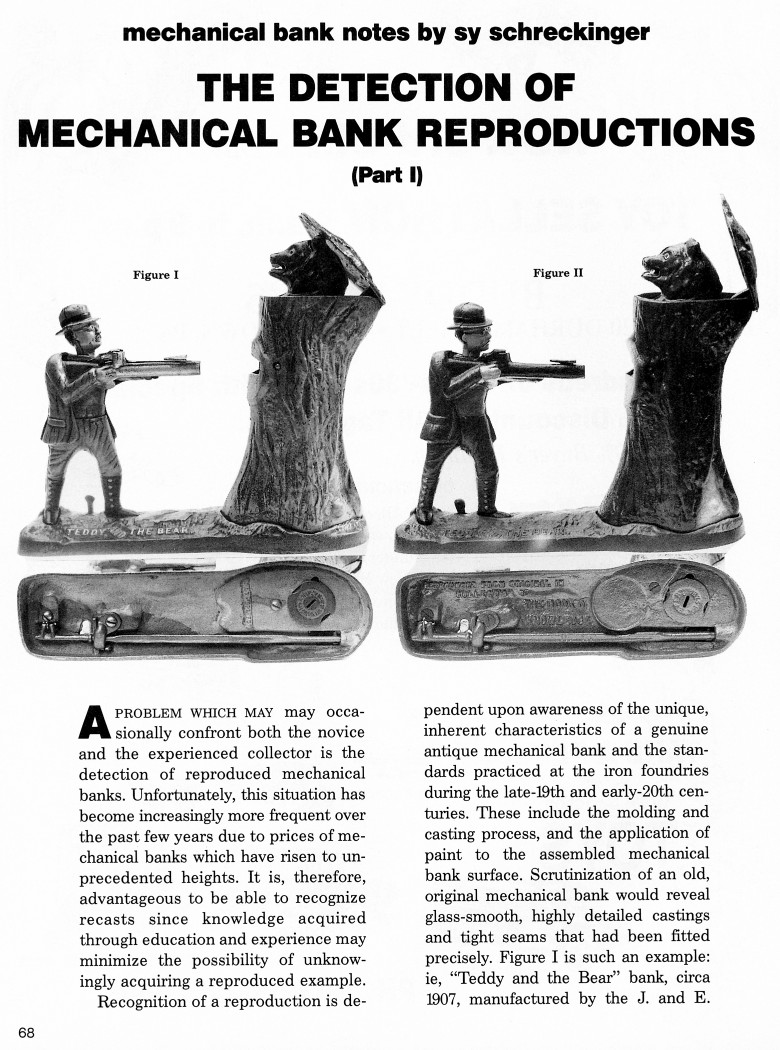

Recognition of a reproduction is dependent upon awareness of the

unique, inherent characteristics of a genuine antique mechanical bank and

the standards practiced at the iron foundries during the late-19th and

early-20th centuries. These include the molding and casting process, and

the application of paint to the assembled mechanical bank surface. Scrutinization of an old, original mechanical bank would reveal

glass-smooth, highly detailed castings and tight seams that had been

fitted precisely. Figure I is such an example: i.e., "Teddy and the Bear"

bank, circa 1907, manufactured by the J. and E. Stevens Company of

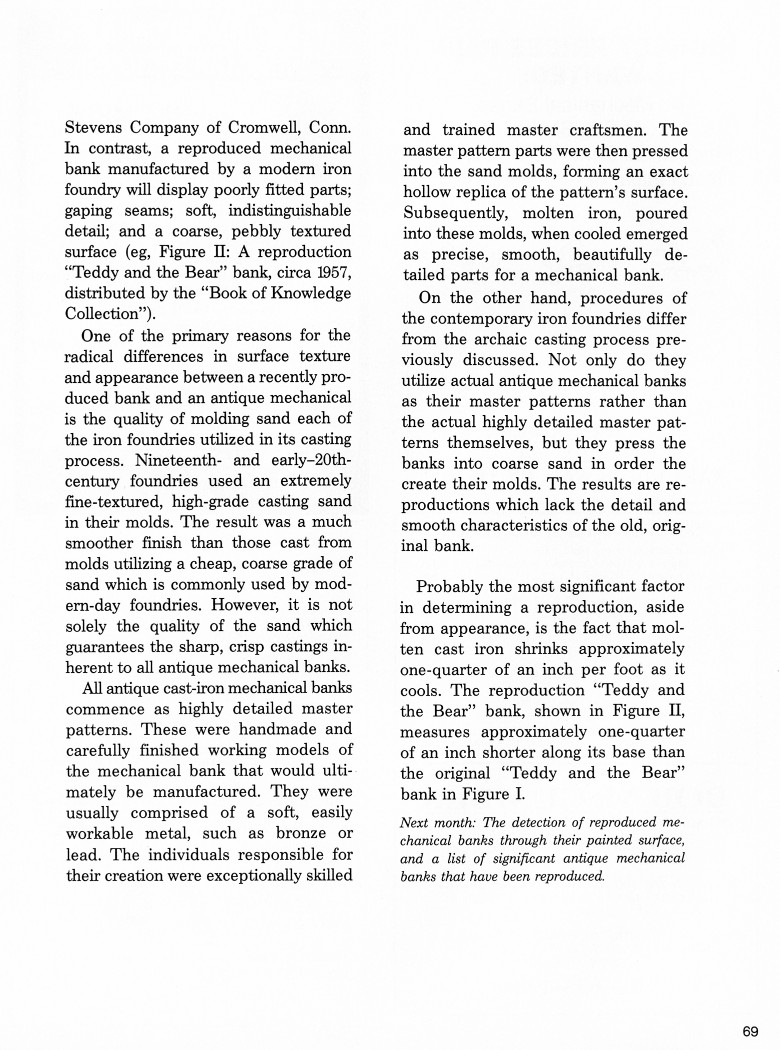

Cromwell, Conn. In contrast, a reproduced mechanical bank manufactured by

a modern iron foundry will display poorly fitted parts; gaping seams;

soft, indistinguishable detail; and a coarse, pebbly textured surface (eg,

Figure II: A reproduction "Teddy and the Bear" bank, circa 1957,

distributed by the "Book of Knowledge Collection").

One of the primary reasons for the radical differences in surface

texture and appearance between a recently produced bank and an antique

mechanical is the quality of molding sand each of the iron foundries

utilized in its casting process. Nineteenth and early-20thcentury

foundries used an extremely fine-textured, high-grade casting sand in

their molds. The result was a much smoother finish than those cast from

molds utilizing a cheap, coarse grade of sand which is commonly used by

modern-day foundries. However, it is not solely the quality of the sand

which guarantees the sharp, crisp castings inherent to all antique

mechanical banks.

All antique cast-iron mechanical banks commence as highly detailed

master patterns. These were handmade and carefully finished working models

of the mechanical bank that would ultimately be manufactured. They were

usually comprised of a soft, easily workable metal, such as bronze or

lead. The individuals responsible for their creation were exceptionally

skilled and trained master craftsmen. The master pattern parts were then

pressed into the sand molds, forming an exact hollow replica of the

pattern's surface. Subsequently, molten iron, poured into these molds,

when cooled emerged as precise, smooth, beautifully detailed parts for a

mechanical bank.

On the other hand, procedures of the contemporary iron foundries

differ from the archaic casting process previously discussed. Not only do

they utilize actual antique mechanical banks as their master patterns

rather than the actual highly detailed master patterns themselves, but

they press the banks into coarse sand in order the create their molds. The

results are reproductions which lack the detail and smooth characteristics

of the old, original bank.

Probably the most significant factor in determining a reproduction,

aside from appearance, is the fact that molten cast iron shrinks

approximately one-quarter of an inch per foot as it cools. The

reproduction "Teddy and the Bear" bank, shown in Figure II, measures

approximately one-quarter of an inch shorter along its base than the

original "Teddy and the Bear" bank in Figure I.

Next month: The detection of reproduced mechanical banks through

their painted surface, and a list of significant antique mechanical banks

that have been reproduced.

|